It is possible to create complex layered shapes that are difficult to manufacture with conventional processing methods! AM technology that achieves optimization.

The features of our AM solutions lie in our expertise in design and analysis, which are essential in the pre-process of additive manufacturing.

In AM, a variety of considerations are required to achieve optimal design from material selection, shaping, to secondary processing. Leveraging the design, analysis, and inspection technologies we have cultivated so far, we aim to make broad proposals for applications in new industries, from decorative parts to functional components.

Our "ARGO500" boasts a wide variety of usable materials, and a significant feature is its compatibility with materials other than those from Roboze.

Additionally, it has a high-temperature chamber function, allowing for the shaping of super engineering plastics, and its relatively large build size is also an advantage, accommodating shaping and evaluation for material development purposes.

[Features]

- Expertise in design and analysis in the pre-process of additive manufacturing

- Achieving optimal design from material selection, shaping, to secondary processing

- Broad proposals leveraging the design, analysis, and inspection technologies we have developed

*For more details, please refer to the PDF document or feel free to contact us.

![[Reference] Guide to Introducing 3D Printing in Manufacturing Lines](https://image.mono.ipros.com/public/product/image/99e/2000543000/IPROS33622611885216935892.png?w=280&h=280)

![[Column] Key Points for Estimating 3D Printing Services](https://image.mono.ipros.com/public/product/image/93f/2001455124/IPROS11150412000312378993.png?w=280&h=280)

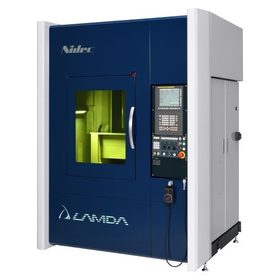

![[Equipment Introduction] Machining, Heat Treatment, Casting, Inspection Equipment](https://image.mono.ipros.com/public/product/image/be3/2001183933/IPROS70582254147219917554.jpeg?w=280&h=280)

![[Information] Metal Additive Manufacturing - 5 Representative Applications](https://image.mono.ipros.com/public/product/image/34f/2000542983/IPROS84214049895242102336.png?w=280&h=280)